Wholesale High-Quality Silk Pillowcase For Skin Manufacturers Suppliers – Printed pattern 19MM 100% Mulberry Silk and Tencel fabric Pillowcase for children – Huierjia

Wholesale High-Quality Silk Pillowcase For Skin Manufacturers Suppliers – Printed pattern 19MM 100% Mulberry Silk and Tencel fabric Pillowcase for children – Huierjia Detail:

Introduction

|

Pillow Cases Size(inch/cm) |

||

| Double | 21’’x30’’ | 50cmx76cm |

| Twin | 21’’x30’’ | 50cmx76cm |

| Full | 21’’x30’’ | 50cmx76cm |

| Single | 21’’x30’’ | 50cmx76cm |

| Queen | 21’’x30’’ | 50cmx76cm |

| King | 24’’x39’’ | 60cmx100xm |

| Super King | 24’’x39’’ | 60cmx100xm |

Detailed Introduction

1.Premium 100% Breathable Cotton

Made with premium quality pure cotton,300 thread count weave offers breathable feature and smooth to the touch,produces super soft feel which are durable and hypoallergenic

2.Envelop Closure

These pillowcases are easy to care.There is on zipper,so it’s very easy to put in or take out the pillow.,Pillowcase with envelope design,simple and stylish,washable ie more convenient.

3.silk Screen Printing

Silk screen printing can print an any designs as customers’ requirement.The Pattern is only on the front side,the back is white natural cotton fabric.

Packing

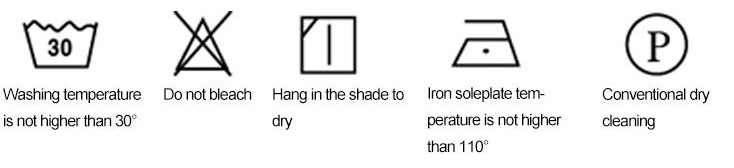

Washing Instructions

Our Service

We can provide customized sizes and packaging according to customers needs.

You can choose our designs, also you can directly send your designs to us.

Customized Logo and Label are accepted, you can send them to us.

Contact us to discuss more, we will do our best in every detail.

FAQ

Printing process is the use of dyes or pigments on the textile printed pattern process. Printing has fabric printing, wool printing and yarn printing, and fabric printing is the main. Wool printing is used to make mixed color tweed; yarn printing is used to weave special style of color patterned fabrics. Fabric printing has a long history. China in the Warring States period has been applied to openwork version of printing (see the history of Chinese dyeing). In India, wooden stencils were used in the 4th century B.C. Continuous intaglio cylinder printing began in the 18th century (see cylinder printing). Screen printing was developed from the openwork version and is suitable for small batch and multiple printing of easily deformed fabrics.

In the 1960s, metal seamless circular screen printing began to be used, providing the conditions for continuous production, and its efficiency is higher than that of flat screen printing. In the 70′s, the method of spraying liquid printing controlled by electronic computer program was also researched, in which many combinations of spraying mouths intermittently spray various colors of dyeing liquid to form colorful patterns, mainly used for carpet printing.

Product detail pictures:

Related Product Guide:

It is a good way to enhance our products and solutions and repair. Our mission will be to build creative solutions to consumers with a great experience for Wholesale High-Quality Silk Pillowcase For Skin Manufacturers Suppliers – Printed pattern 19MM 100% Mulberry Silk and Tencel fabric Pillowcase for children – Huierjia , The product will supply to all over the world, such as: Portland, Luxembourg, French, We care about every steps of our services, from factory selection, product development & design, price negotiation, inspection, shipping to aftermarket. We have implemented a strict and complete quality control system, which ensures that each product can meet quality requirements of customers. Besides, all of our products have been strictly inspected before shipment. Your Success, Our Glory: Our aim is to help customers realize their goals. We are making great efforts to achieve this win-win situation and sincerely welcome you to join us.

I love working with this company! They are easy to work with and the product turns out great. Highly recommend!